bstract

Within the lifetime of most reverse osmosis (RO) systems some fouling will adversely affect

membrane performance.One of the major foulants identified on lead membranes during a

decade of membrane autopsy at the Genesys Membrane laboratory is biological fouling

(biofouling).

All raw water sources contain microorganisms such as algae, bacteria and fungi. They also

contain compounds which provide nutrients and energy sources which promote biological

growth. In addition current methods of control such as chlorination will increase the

availability of nutrient compounds.

The effects of biofouling on membrane operation include a reduction in flux, increase in

pressure drop and salt passage and potentially membrane degradation and failure. Current

technology favours the use of biocides to control biofouling; however bacteria in biofilm are

more resistant to biocides than planktonic organisms. In addition using biocides produces an

accumulated biomass which encourages active re-growth of the population. Therefore the

successful approach must kill the biological population and successfully remove it from the

membrane surface to prevent rapid re-growth.

This paper explores the processes for developing and testing a cleaning product Genesol 703

which removes biofouling from RO/NF/UF systems. The results of removing biofilm from

membranes are presented. Product efficacy was determined by comparison of membrane flux

rates before and after cleaning and visual inspection by scanning electron microscopy (SEM).

The results demonstrate that Genesol 703 is a technically and economically viable cleaning

chemical product for the removal of biofouling from membranes

1. Introduction

Biofouling is referred to as the undesired development of microbial layers on surfaces [1]. All

raw water sources and therefore reverse osmosis (RO) feed waters contain microorganisms

such as algae, bacteria and fungi, in addition they contain both nutrient and energy sources

which promote growth of the bacterial population.

Biofouling has been recognized as the most serious problem in RO systems [2,3]. Membrane

Autopsy procedures at the Genesys laboratories in Madrid have proved that over a 5 year

period biofouling accounts for 35% of failures of all membranes tested; the most frequently

detected foulant.

Figure 1.The main types of foulant identified on membrane elements from the first position during autopsy

(2001-2007).Source: GMP laboratories statistics

The effects of biofouling on both Brackish water (BWRO) and Sea Water (SWRO) RO

membranes include an increase in pressure drop, decrease in flux, and can also affect salt

passage. In extreme cases membrane degradation and failure can occur. As all of these

consequences will impact directly on operating expenditure a variety of different operating

procedures are regularly implemented during pre-treatment to control the population of

microorganisms in RO feed waters.

Pre-treatment and chemical procedures are required to prevent and control membrane fouling

but have been found to be rarely totally effective in removing microorganisms and nutrients

from the feed water system. In addition differences in RO system design, operating

procedures and the ability of microorganisms to adapt and multiply successfully in membrane

environments makes it difficult to rely on a single method of control. In addition some of the

methods currently in wide use to control biofouling can encourage growth if applied

incorrectly. The following sections give an overview of some of the processes involved in

biofouling and the development of a specific cleaning product. Results from laboratory scale

tests are presented with an explanation of the unique mechanisms which make this product

effective.

2, Background –Membrane biofouling.

All RO feed water sources contain a population of microorganisms and compounds which act

as nutrients or energy sources. It is not the purpose of this paper to outline in detail the

35%

29%

29%

7%

Biofilm&Organic matter

Colloidal/particulate matter

Scales&Inorganic deposits

Not detected

Types of foulants detected in RO membranes

autopsies (2001-2007)

Biofilm&Organic matter Colloidal/particulate matter

Scales&Inorganic deposits Not detected

different types and species of microorganisms which may be present and also the complex

methods of interaction and protection they employ to survive and multiply in the aquatic

membrane environment. A brief description of the microbial populations in the membrane

environment will help explain how current control methods are limited and how a dual

approach is required to control operational problems associated with membrane biofouling.

In RO systems the pre-treatment, pipe work and membrane elements provide a large surface

area for the attachment and growth of free living bacteria entering in the feed water. A

biofilm is described as bacterial aggregates attached to a surface; the biofilm structure

includes a matrix of bacterially produced Extracellular Polymeric Substances (EPS). The EPS

is composed of polysaccharides, proteins and nucleic acids [4] and has been proven to play a

major role in biofouling formation and its behaviour; effectively altering the porosity,

density, water content, charge and sorption properties [1,5] of the biofilm. EPS enhances the

structural integrity and adhesiveness of biofilms through 3 different forces:1. electrostatic, 2.

hydrogen bonds and 3. London dispersion forces [6]. This adhesiveness and elasticity makes

the biofilm difficult to remove from membrane surfaces and also provides protection from

biocides. In addition the presence of divalent cations such as calcium and magnesium

increase the strength of biofilm by forming salt bridges between the membrane surface and

negatively charged bacteria [6].

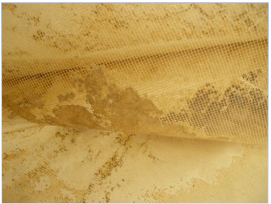

Figure 2.- Detail of a biofilm fouled membrane with deposit attached to spacer material.

2.1 Methods of Control biofouling

Genesys Membrane Autopsy results prove that biofilm formation does not occur equally

within all areas of the membrane system, as the RO membranes filter out bacteria and

nutrient sources from the feed water the bulk of the biofouling occurs in the first element of a

pressure vessel. However in extreme cases formation can occur on the product side

contaminating permeate water. Time of formation differs widely between RO systems; from

a few days to a few weeks, however in an RO system operating on biologically active feed

water a biofilm will appear within 3-5 days of inoculation [7].

In order to limit biofouling in a membrane system bacteria and nutrient/energy sources are

intended to be removed from the feed water (preventive action). Pre-treatments in RO

facilities have largely evolved in the last years including in some cases membrane

technologies as Microfiltration (MF) or Ultrafiltration (UF). Even these last generation and

extensive pre-treatment designs are rarely a 100% efficient processes and survival of a very

small number of viable cells will lead to multiplication and possible biofouling in the

membranes. In addition to this approach disinfection stages in the pre-treatment system using

biocides or UV are also used. Factors which must be considered when designing a method of

disinfection include feed water quality (particularly; bacteria levels, pH and analysis of both

organic and inorganic compounds), contact time and membrane element type (material). Cost

of biocide application must also be considered as dosage rates will be affected by the size of

the system and level of biofouling.

The chemistry and use of chlorine as a disinfectant is widely covered in literature. It is

extensively used in industrial and municipal applications due to its’ relatively low cost and

widespread availability. It has significant limitations in terms of application in RO systems;

thinfilm composite polyamide membranes are sensitive to levels of chlorine with oxidative

degradation occurring at between 200-1000 hours of exposure to 1ppm of free chlorine [7],

therefore chlorine must be removed from the feed system prior to entering the membrane,

either by activated carbon or dosing Sodium Metabisulphite. Therefore any viable bacterial

population or biofilm in the membrane will not be affected. In addition chlorine breaks down

natural organic matter (NOM) present in the feed water to more easily biodegradable

products offering a nutrient source to micro-organisms. As no chlorine is present on the

membrane surface biofilm growth can occur leading to a requirement for more frequent

sanitization. At this point, it is important to consider the role of EPS in membrane fouling and

performance rather than counts on viable cells on membranes. Within a membrane system a

biofilm level of 10³cfu/cm² for aerobic bacteria is considered normal with operational

problems generally occurring with bacterial counts >105cfu/cm² [8]. Recent studies show that

chlorine-inactivated bacteria may also produce a biofouling layer on the RO membrane

surface [9] .Chlorine is effective in inactivating microorganisms but not in decreasing EPS

concentration, so no improvements in flux decline related to these fouling processes are

observed [5].

Alternative non-oxidising biocides such as DBNPA (2,2-dibromo-3-nitrilopropionamide) and

isothiazalones are approved by membrane manufacturers; however dose rates and therefore

application costs are significantly higher than chlorine making continual dosing impractical.

These chemicals are also not approved for dosing online in potable applications.

Importantly these biocide products are unable to adequately penetrate the protective biofilm

layer and lyse/dissolve these foulants thus preventing re-growth on the membrane [9].

2.2 Membrane Cleaning

Membrane cleaning-in-place (CIP) is also used as a means of biofouling control, primarily

aimed at disrupting and removing the biofilm layer from the membrane system. As reported

by C. Whittaker et al [9] “strongly bactericidal compounds were not necessarily effective in

removing biofouling layers, and cleaning solutions that were effective in biofilm removal

were not necessarily bactericidal”. In any case, disinfections have to be completed by the

removal of the killed cells, which otherwise would adhere to membrane surface.

In practice CIP processes do not fully remove biomass from membranes, particularly in

severe cases when plugging of the feed path restricts transport of cleaning chemicals into the

blocked region. The remaining biomass, rich in nutrients, allows for rapid re-growth after

cleaning. The use of CIP as a means of removing biofilm is often ineffective due to a

combination of incorrect chemical selection – inability to fully penetrate the biofilm layer,

poor cleaning practice (with respect to parameters such as pH, temperature, contact time

and/or improper recirculation flow rates) and delays in CIP application. Poorly applied

membrane cleaning procedures will limit the recovery of the system to design operating

parameters (flux, pressure drop and permeate quality) and incomplete removal of biomass

may accelerate the growth of bacteria in other parts of the system.

3. Genesol 703 – new cleaning approach

Cleaning agents can affect fouling materials present on a membrane surface in three ways: (i)

foulants may be removed, (ii) morphology of foulants may be changed (swelling,

compaction) and/or (iii) surface chemistry of the deposit may be altered, such that the

hydrophobicity or charge is modified [10]. Reported foulant-cleaning agent reactions are

hydrolysis, peptization, saponification, solubilisation, dispersion (suspension) and chelation.

If an inappropriate cleaning agent is chosen negative effects can appear and membrane

performance can be adversely affected. Membrane manufacturers [11] clearly state the

consequences of applying inefficient cleaning techniques: “If foulant is not successfully

removed, the membrane system performance will decline faster as it is easier for the foulant

to deposit on the membrane surface area. The time between cleanings will become shorter,

resulting in shorter membrane element life and higher operating and maintenance costs.Most

effective cleaning allows longer system operating time between cleanings and results in the

lowest operating costs”.

Genesol 703 was developed and tested as an effective cleaning compound for the removal of

clay deposits [12]. Genesol 703 is a 100% active chemical powder based on a combination of

high pH phosphate cleaners, a blend of chelants, surfactants and other active compounds. The

product is approved under NSF/ANSI 60 guidelines.This combination of products has a

detergent and surfactant effect on the colloidal foulants and in addition creates high ionic

strength at the membrane surface. Due to the relevance of biofouling problems detected in

Genesys Membrane Products laboratories (detected in 35% of membranes autopsied) and

synergistic properties of this formulated cleaner, trials against biofilm removal under

laboratory conditions were conducted.

The Genesol 703 mode of action can be described as follows: the first stage of attack occurs

at the water/surface inter-phase of the biofilm and is due to the synergistic mode of operation

of the combined speciality chemicals. This process works by reducing the surface tension of

the deposit allowing the surfactant to become more effective in overcoming the

impermeability of the EPS material; this allows the cleaning solution to penetrate into the

biofilm structure. The foulant layer then becomes more porous increasing the permeability to

water and consequently increasing the surface area of the deposit allowing more active

chemical to penetrate and disrupt the “body” of the deposit. Genesol 703 provides a

secondary physical action which increases cleaning efficiency at the membrane surface

allowing a “double edged” approach to deposit removal. This action removes blockages from

the membrane pores caused by the biofilm layer.

In normal operation of an RO system the pressure provided by the high pressure pump (HPP)

overcomes the osmotic pressure of the feed water. During cleaning, the Genesol 703 solution

is introduced to the system at a cleaning pressure below 4 bar. The feed water salinity will

increase. It is possible that at the membrane surface the local osmotic pressure may become

higher than the Net Driving Pressure (NDP) of the feed water. If this were the case then

potentially there may be some localised forward osmosis taking place. Any movement of

permeate water through the membrane to the feed water may assist lifting of the biofilm

around the membrane pores. This in turn would allow greater access to the surfactant

cleaning chemicals to remove deposits. The removal of deposits away from the membrane

into the concentrate stream is likely to help minimise membrane abrasion. This phenomenon

may go some way to explain the effectiveness of the cleaning formulation. Further work is

required to try and observe what is actually happening at the membrane surface during

cleaning.

In addition to the effectiveness of Genesol 703 in removing biofilm deposits its application

also serves as a means of “shock treatment” of a reverse osmosis system to reduce the

biofouling potential through lysis of microorganisms; in turn this helps to prevent further

system contamination. Cell lysis occurs due to the semi permeable nature of the membrane

surrounding the microorganism; the cleaning solution creates the movement of water from

the cell cytoplasm resulting in the eventual removal of the membrane from the cell wall. In

addition to removing the biofilm layer from the membrane surface this effect helps to destroy

remaining active cells preventing swift repopulation of the system.

Laboratory tests (as indicated below) proved this product to be much more effective at

removing biofouling deposits than conventional acid and alkaline cleaning products.

5. Testing Genesol 703 efficiency – Experimental set up and procedures

In order to establish the efficiency of Genesol 703 in removing biofouling from a membrane

surface, several cleaning tests were carried out in the Genesys Membrane Products S.L.

laboratories using membrane coupons from three actual RO membrane elements in which

biofouling was identified. In order to verify that the deposits on these membrane elements

were mainly composed of biofilm, several observations (deposit morphology, moisture and

organic matter content) and techniques were taken into consideration:

a) Microbiological counts on membrane surface

b) Membrane surface/deposit inspection by Scanning-electron microscopy – Energy

dispersive X-ray analysis (SEM-EDAX) is used to study the membrane surface and to

verify the elemental composition of its foulant and deposits detected. Elemental

determination with the SEM-EDXA system is based on analysis of X-rays produced

via electron beam excitation of a sample area.

c) Foulant/membrane surface analysis by Attenuated Total Reflectance Infrared

Spectrometry (ATR/IR). This technique can provide valuable information related to

chemical structures and characterize the fouling layer from membrane surfaces.

In the mid-infrared, absorption of radiation is related to fundamental vibrations of the

chemical bonds. Internal reflection spectrometry provides information related to the

presence or absence of specific functional groups. IR spectra were carried out for the

foulant taken from the membrane surface in all case studies. In all of the 3 cases the

identified compounds are protein derivatives that are commonly related to the

presence of microorganisms / biofilm (bands at 1639 and 1561 cm-1

).

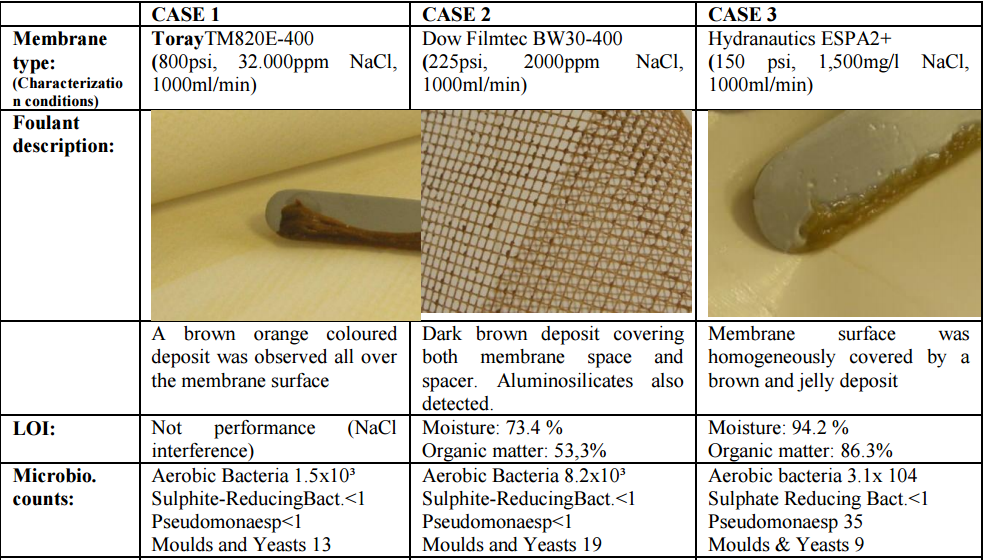

Data for membranes selected for this study are summarized in Table 1.

Cleaning experiments were performed with a laboratory scale cross-flow test rig unit.

Rectangular flat sheet membrane coupons from RO elements were housed in a stainless steel

cell, with an effective membrane area of 231cm2

. Feed water was circulated under the

characterisation conditions (pressure and salinity) established by the membrane element

manufacturer in order to establish a baseline for each membrane sample. Data achieved is

normalized to 25ºC conditions. Different cleaning solutions were later re-circulated at 40 psi.

The cleaning chemical used on each membrane and the test conditions are described below.

After re-circulating the cleaning solution the membrane is rinsed with deionised water and

characterised with the same conditions as used in step one. The cleaning efficiency of the

product is then evaluated in terms of flux and rejection percentual variations. Additional

analysis and visual inspection can be carried out to provide further evaluation.

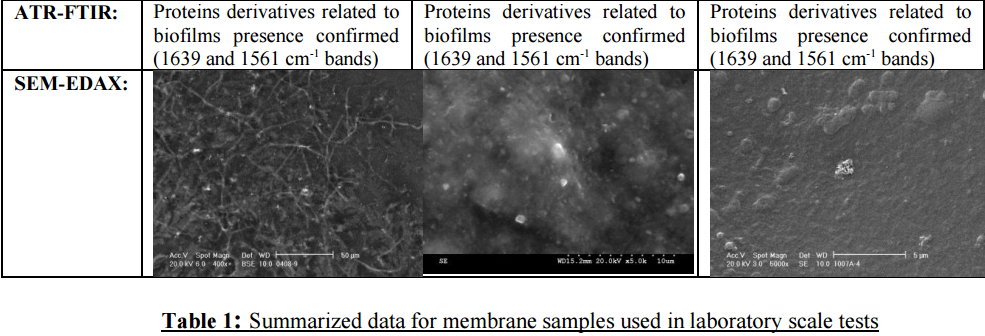

6. Testing Genesol 703 efficiency – Results and discussion

In order to check Genesol 703 efficiency, several cleaning programs were designed according

to the membrane manufactures guidelines for removing this type of foulant. Established

limits of pH and temperature have also been applied. In order to achieve comparative results,

contact time in each trial has been set up in 2 hours. The results obtained in the different

cleaning tests and the conditions applied (temperature, pH and contact time) are summarized

in Table 3. Figure 3 depicts a graphical summary from different case studies showing the

percentage flux change of each membrane coupon section after the cleaning process.

Individual chemical cleaning solution relate to those shown in table 3.

The data obtained in this experimental work demonstrates that Genesol 703 is more efficient

in removing this kind of biological foulant than the other chemical blends in term of flux

improvements. With regards to the evaluation of salt rejection data the results are

inconclusive – as in most cases a decrease in salt rejection was observed after chemical 611 925 1044 1235 13181408 1379 1453 1544 1655 2852 2924 3399

GA071136

PROTEINS FROM URINARY SEDIMENTS

1.3 Absorbance

4000 3500 3000 2500 2000 1500 1000 500

Wav enumbers (cm-1)

cleaning. It is important to point that in this experiment fouled membrane samples come from

real plants and they have been operating under fouling conditions a variable period of time in

each case. Although biofilm has been documented as more significant fouling in these

samples, it is widely assumed that biological fouling is seldom found alone (“composite

fouling”) and its properties for enhancing particulate fouling.A reasonable explanation to

these results would be membrane abrasion which is frequently documented in membranes

fouled by colloids [12] and operation under high differential pressure conditions.

read more at

http://www.genesysro.com/uploads/docs/GenesysInternational-RemovingBiofilmfromMembranes.pdf